Making things stick with sustainable science

CFANS researchers discover bio-based solutions for the commercial adhesives market

COREY WALES, COLLEGE OF LIBERAL ARTS, BS TECHNICAL WRITING AND COMMUNICATION ‘21

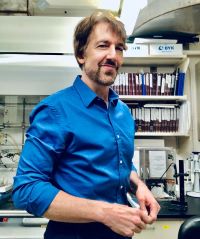

Steve Severtson, PhD, knows a thing or two about “sticky” situations. As a professor and scientist in the Department of Bioproducts and Biosystems Engineering (BBE) at the University of Minnesota’s College Food, Agricultural and Natural Resource Sciences (CFANS), he’s leading research in the area of industrial adhesives, focused on those partially or entirely made of materials derived from biomass (renewable organic material).

According to a report published by Allied Market Research, the global demand for industrial adhesives, heavily used by the packaging, construction, and transportation industries, is growing. It generated $39 billion in 2019 and is projected to hit $54.9 billion by 2027.

As governments worldwide enact regulations to control environmental pollution and more consumers continue to demand biodegradable products across supply chains, the market size for bio-based adhesives is expanding as well — with expected growth from $6 billion in 2020 to almost $10 billion by 2025.

According to Severtson, companies implementing sustainable practices are moving to eco-friendly packaging, but current adhesive materials tend to interfere with processes such as recycling and composting. His research looks at the redesign of adhesives to promote a more circular consumption model for disposable products.

Bio-based benefits

At CFANS, Severtson teaches Bioproducts and Biosystems Engineering courses and conducts laboratory research on wetting, adhesion, and materials, including adhesives, coatings, and composites. His current research focuses on bio-based pressure-sensitive adhesives, (PSAs) made partially or entirely of materials derived from biomass, or renewable organic material, such as plants like soybeans and corn. Severtson’s research develops biomass monomers, small reactive molecules, to generate high biomass content polymers. His group also modifies nanoparticles derived primarily from cellulose for use with adhesive polymers to enhance their performance. In general, his work aims to synthesize and formulate adhesives designed for enhanced recovery and degradation.

Adhesives containing renewable biomass tend to biodegrade and are responsive to treatments such as industrial composting. Although adhesives typically comprise only a fraction of waste streams, their presence often interferes with recycling major waste components such as paper and plastic bottles. Adhesives can also contaminate composting operations when combined with products designed for bioremediation and diminish compost quality.

Noting that major retailers and brands have made commitments to eco-friendly packaging, such as 100 percent recyclable, reusable, or industrial compostable by 2025, Severtson’s research is not looking for solutions that might be viable a decade from now. Instead, his efforts are on technologies that will work with the existing infrastructure. He believes such technologies can bridge the divide between an industry currently dependent almost exclusively on oil and natural gas and its future in which renewable biomass is a primary feedstock.

Hybrids mix it up

Severtson is hoping to move several of the current technologies his group is working on beyond the laboratory. “We’ve had success commercializing our research in the past, and I believe these current projects have promise,” he said. “For example, Franklin International plans to generate pilot-scale batches of our new nanocomposite PSA early next year, with the potential for production-scale runs soon after.”

Some of the more exciting technologies developed in Severtson’s labs include mixed or hybrid adhesives. “We generated these PSAs through the copolymerization of traditional monomers and those derived from biomass,” said Severtson, explaining that they grow oligomers primarily consisting of lactide from acrylic head groups. “These reactions generate large monomers, called macromonomers, capable of reacting with fossil-sourced chemicals used in commercial polymeric products. This approach allows us to drop renewable biomass into existing commercial formulations often with no changes to the manufacturing process and little or no impact on product performance.”

Recently, his team has been tailoring macromonomer composition and structure to enhance performance and provide greater control over polymer properties. “An advantage of this technology is that we can apply it to a broad range of commercial products, not just adhesives,” said Severtson.

Partners in production

Severtson is approaching his research on bio-based adhesives with industry partners such as Franklin International, H.B. Fuller, Arkema, and others. These companies supply materials, equipment and insights not easily accessible to academics. For example, Severtson points out that “the industry produces most commercial PSA using emulsion polymerization, which involves feeding monomers to growing polymer particles from an emulsion to generate a latex product. Such reactions are complex, multiphase processes involving a broad range of chemical components. The companies we work with have extensive experience in this area. Their help has significantly reduced the time required to obtain commercially viable, bio-based latexes.”

Severtson and his team also work with various University of Minnesota research centers, including the Nano Center, the Nuclear Magnetic Resonance Spectroscopy (NMR) Center, and the College of Science and Engineering Characterization Facility (CharFac), to characterize their polymers and latexes. In addition, his team is currently working on establishing a characterization lab on the St. Paul campus. Such a center would provide access to some of the more heavily used characterization tools, which he hopes will help facilitate bio-based materials research and foster greater collaboration within CFANS. He believes it will also enhance teaching materials science concepts by providing hands-on experience with standard characterization techniques.

Teaching tomorrow’s leaders

Severtson has many people on his team aiding in his research. For example, Drew Hauge (BS, Bioproducts and Biosystems Engineering '14 and pictured at the top of this story) is no stranger to the Severtson lab. Hauge worked in the same lab for three years as an undergraduate and overseas with one of the group's international partners. Hauge oversees research on emulsion polymerizations and surface modifications of cellulose nanocrystals. "I appreciate the freedom Steve allows me to pursue my ideas. I don't think I would ever have this level of autonomy working in the industry," said Hauge.

Severtson also employs a team of undergraduates in his lab including Tiffany Cardoza, Mario Tuccitto, Jacob Votava, and Brenda Zhang. According to Severtson, much is expected from these undergraduate researchers, adding that they tend to take on responsibilities usually assigned to graduate students.

Another member of Severtson's team is Ben Tansi, PhD, a chemistry graduate from Penn State University. At the U of M, Tansi is a postdoctoral scholar primarily responsible for characterizing chemicals and materials, including imaging fracture surfaces for polymer nanocomposites films, and measuring the properties of surfactants used in mini-emulsion and macro-emulsion polymerizations.

"One of the great benefits of developing materials for commercial applications is working with industrial researchers such as Dr. Puran De from Franklin and Dr. Wenjun Wu from Arkema. I have learned a great deal from this experience,” said Tansi.

Severtson also collaborates with BBE Professor Jiwei Zhang, PhD, an expert in fungal biotechnology and remediation, on a MnDRIVE project to identify fungi capable of degrading latex polymers. Jesus Castaño Urueña, PhD, a 2021 graduate of the University of Minnesota, is the postdoc leading the research. He has already made significant progress in identifying potential species for the design of biological remediation processes. Severtson is excited about this research direction, noting that this is the first time he has had the opportunity to collaborate with someone with Zhang's skill set.

All of this adds up to making a lot of things stick, from science to sustainability to student success. That's something we all can adhere to.

Impact Winter 2022: Table of Contents

A shortened version of this article was featured in Impact, a quarterly print publication from CFANS.