Behind the research: Exploring the potential of cold plasma technology

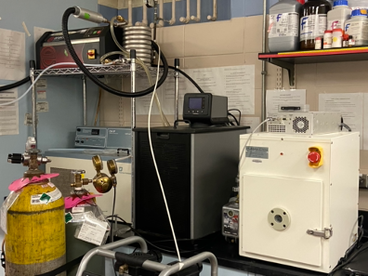

George Annor is an Assistant Professor in the Department of Food Science and Nutrition and is the General Mills Endowed Professor in Cereal Chemistry and Technology. Part of his research centers around using cold plasma, an emerging technology for processing food. George’s past research focused on using the cold plasma to modify starches and other foods, and now he has expanded his studies to explore other applications of the technology. We talked with George about his research using this emerging technology.

Cold plasma is an emerging technology for processing food. How does cold plasma technology work?

Cold plasma is generated when electrical energy is applied to a gas, causing the ionization of the gas to generate very reactive molecules or particles. A very simple way to understand how cold plasma works is to think of fluorescent tubes and neon signs. Inside a neon sign bulb there is neon gas and helium gas that glows when you flip a switch on the wall to introduce electricity. The electrical energy that is introduced into the neon bulb for example excites the gas molecules, causing them to release energy in the form of light. For cold plasma, when electrical energy is applied to air, it creates very reactive charged particles that can change the properties of food when the two come in contact.

Why did you decide to focus your research program on cold plasma technology?

The need for novel food processing technologies that are also environmentally friendly is what drew me to cold plasma technology. I see cold plasma as a potential alternative to existing food processing technologies that are based on the use of chemicals. This technology has the potential to change how we process or modify foods in the future. Not only that but it also has the possibility to increase food production by increasing seed germination rates and seed vigor.

Much of your work has focused on using cold plasma to modify starches. Why are starches modified in foods? How could cold plasma technology change how starches are modified in the future?

Starch is used as a gelling, thickening, stabilizing, and flavor encapsulating agent in the baking, brewing, and confectionery industries. However, starch in its native form does not dissolve in water, is unreactive, and is unable to withstand some of the very harsh processing conditions that are used for foods. Currently, chemicals are used to modify starches to enhance their solubility, textural properties, and heat tolerance for diverse industrial applications. Unsurprisingly, the use of these chemicals raises a lot of concerns from consumers and environmentalists. Cold plasma could replace the use of these chemicals to modify starches.

In my lab, we’ve studied how we can use cold plasma to improve dough properties of soft as well as hard wheat and intermediate wheatgrass. The study showed that flour from the different grains studied had a different response to cold plasma. Plasma treatment improved the dough stability of soft wheat flour. Dough stability is a measure of a flour's tolerance to mixing and is related to the properties of gluten in the flour. Higher stability flours often result in a higher price. These results showed that by treating soft wheat with cold plasma, we can improve the baking properties of the flour.

You noted cold plasma could also help increase food production. Can you tell us more about that?

Preliminary experiments in my lab showed that when soybean seeds were treated with cold plasma for about 10 min and then germinated, about 30% more of the seeds treated with cold plasma germinated when compared to the untreated soybeans. Currently, we’re collaborating on research with the University of California Davis, University and Maryland, and Cornell University to investigate the enhancement of specialty crop seed germination, seeding vigor, and pest management using cold plasma technology. Tomato, Blue Boy and poppy seeds are amongst some of the seeds we're studying.